Overview of Silver Nanowires

Aaron Linder

1. Introduction

Silver Nanowires are some of the most modern materials being available on the market. There is many recent publications and academic research about Silver Nanowires and what is the methods of fabrication, synthesis, and what are the properties of these nanowires. This paper will attempt to make a summary of Silver Nanowires various topics in a short summary.

2. Properties of Silver Nanowires

a. Mechanical Properties of Silver Nanowires

In recent years nanowires, have attracted significant interest because of their superior mechanical properties [5]. Silver Nanowires Grown in the á1 1 2ñ direction have been shown to have significantly increased yield strength compared to Ag bulk. Size dependent Young’s Moduli have been reported for FCC metals, both in simulation and experimental studies. [1-4]

b. Electrical Properties of Silver Nanowires

Silver is considered a 1-d nanomaterial so it experiences Ballistic Transport. Ballistic transport means that the nanowire has negligible electrical resistivity caused by scattering. Without scattering, electrons simply obey newtons second law of motion at non-relativistic speeds. There is only a base resistance once the electrons reach their target of a larger substrate to connect to. This is the basic resistivity of the quantum-mechanical contact resistance, there are other sources of contact resistance, such that as produced of poor coupling between the mesoscopic conductor and the leads. Ballistic conduction occurs when the length of the conductor is smaller than the mean free path of the electron [6]. The lack of impurities that cause elastic scattering in the conduit material is imperative for this to occur; loss of quantization results if this happens.

c. Optical Properties of Silver Nanowires

Silver nanowires and silver-nanowire thin films have attracted much attention due to their extensive applications in Surface-Enhanced Raman Scattering (SERS) and Surface-Enhanced Fluorescence (SEF). [7] Silver nanowires are one of the most extensively studied metal nanostructures for applications in nanoelectronics and nanodevices, due to their novel optical and physical properties, such as dual plasmon resonance bands, strong SERS and SEF activity. [8-11] Plasmonics refers to the study of enhanced electromagnetic properties of metallic nanostructures. The term is derived from plasmons, the quanta associated with longitudinal waves propagating in matter through the collective motion of large numbers of electrons. [8]

Silver Nanowires can be used with other ions and nanoparticles attached to have enhanced fluorescence. High enhancement of fluorescence emission, improved fluorophore photostability, and significant reduction of fluorescence lifetimes have been obtained from high aspect ratio (>100) silver (Ag) nanowires. These quantities are found to depend on the surface loading of Ag nanowires on glass slides, where the enhancement of fluorescence emission increases with the density of nanowires. The surface loading dependence was attributed to the creation of intense electric fields around the network of Ag nanowires and to the coupling of fluorophore excited states that takes place efficiently at 10 nm from the surface of nanowires, which was confirmed by theoretical calculations. [12]

3. Fabrication of Silver Nanowires

a. Polyol Synthesis of Silver Nanowires

One of the methods used to synthesize Silver nanowires is the polyol process. There are many different variables to take into consideration when doing polyol synthesis. The variables are the temperature, injection ate, molar ratio of the precursor poly(vinylpyrrolidone) to silver nitrate, sodium chloride amount, and stirring rate. [14] The reagents to create Silver Nanowires using Polyol Synthesis is Ethylene glycol (>99.0%, J. T. Baker), AgNO3 (99+%, Aldrich), polyvinylpyrrolidone (PVP, MW ≈ 55000, Aldrich), glycolaldehyde dimer (Aldrich), concentrated nitric acid (70% reagent grade, Aldrich),

concentrated hydrochloric acid (37% reagent grade, Aldrich), and acetone (reagent grade, Aldrich).[13]

The chemical kinetics can be mapped out and plotted to reach ideal diameter nanowires but that is not within the scope of this text. This is a reliable method of making nanowires using self-assembly and heterogenous nucleation.

b. Nano-Imprint and E-beam Evaporation

Nano-Imprinting via self-assembly is a popular method of fabricating silver nanowires, afterwards E-beam is used to evaporate the silicon. This method of polymer stamping is very good because it can more accurately control the diameter of the Silver nanowires from a stamp. The only limitation is the wavelength of UV-light which can get down to 15 nm. Most nanowires desired length and diameter are much larger for their optical and mechanical properties to be tuned to the correct size.

This method is an efficient method of producing highly uniform nanowires that is relatively inexpensive compared to etching. According to Feng “Over the past 60 years, numerous techniques have been developed to fabricate nanostructure

arrays, including electron-beam lithography (EBL), chemical vapor deposition (CVD), hydrothermal growth, reactive inkjet printing (RIJ), and

template-assisted synthesis. The EBL and CVD methods are limited by their expensive and time-consuming processes.”[18] This method appears to be one of the most efficient methods overall of producing Silver Nanowires.

c. Electrochemical deposition

Although CVD is classically thought to be one of the worst methods of creating silver nanowires, a variation method has been tested using electrochemical deposition. In a Nature 2016 paper a method for digitally controlled, optically induced electrochemical deposition was journaled. Projected light patterns were used to induce an electrochemical reaction in a specialized sandwich-like microfluidic device composed of one indium tin oxide (ITO) glass electrode and an optically sensitive-layer-covered ITO electrode. Silver polyhedral nanoparticles, triangular and hexagonal nanoplates, and nanobelts were controllably synthesized in specific positions at which projected light was illuminated. The silver nanobelts had rectangular cross-sections with an average width of 300 nm and an average thickness of 100 nm. By controlling the applied voltage, frequency, and time, different silver nanostructure morphologies were obtained.[18]

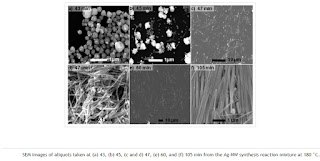

d. Hydrothermal Growth

Much effort has been devoted to the syntheses of silver nanowires, such as electrochemical techniques, templates, and carbon nanotubes, directed synthesis, and polymer-directed synthesis. Recently, Murphy and co-workers have reported a seedless and surfactantless wet chemical approach to prepare silver nanowires. Uniform silver nanowires with diameters of about 100 nm and lengths up to 500 mm were successfully prepared on a large scale through a simple hydrothermal process without the use of any surfactants or polymers. [19]

e. Reactive inkjet Printing

The production of low-cost electronic devices will be revolutionized by the ability to print functional materials. Printed electronics involves the additive fabrication of devices on substrates and over large areas at relatively low temperatures. One of the simplest methods is inkjet printing, a non-contact, additive process which can deposit droplets of ink on a substrate in predefined patterns. Conversely, metallic nanowires, most commonly found as silver nanowires (AgNWs), have recently demonstrated huge potential in transparent electrode applications. Highly conductive silver nanowire electrodes can be fabricated at low temperature and over large areas and are extremely flexible. They have demonstrated sheet resistances as low as 5 Ω/□ for transparencies of 90%. However, while many methods for the deposition of metallic nanowires have been investigated, direct writing of patterned, high-quality silver nanowire networks has proven extremely difficult. To the best of the our knowledge, very few papers have described direct writing of metallic nanowire traces, in this case using inkjet printing.[20] Of the papers that do exist, only one describes the printing of AgNWs in any detail.[21]

4. Uses of Silver Nanowires

a. Thin Films

One use of Silver Nanowires is to create organic solar cells. Using core-shell nanowires, silver electrodes can be created. I am not sure about the details of the construction of solar panel parts. Organic photovoltaics (OPVs) are considered as a future alternative for conventional silicon based solar cells, owing to their low cost, ease of production and high-throughput. The transparent conducting electrode (TCE) is a fundamental component of OPVs. Traditionally, indium tin oxide (ITO) has been mainly utilized as a TCE in OPV applications due to its relatively high transparency and low sheet resistance. However, increasing demand for the optoelectronic devices has led to large fluctuations in ITO prices in the past decade and ITO is known to account more than 50% of the total cost of OPV devices. Thus, it is believed that development of solution-processable alternative materials is of great importance in reducing the cost of OPVs. Silver nanowires have been proposed as a replacement for ITO films in solar cells. [22]

b. Sensors

Silver Nanowires can be used as biosensors, not only because of their surface plasmonics being sensitive to biomolecules, but also as glucose sensors. [23] Integrated sensors for sensing bodily measurements can be used also. [24] Silver nanowire (AgNW) films are particularly promising because they can be fabricated economically from a readily available abundant metal and are flexible enough to enable larger screens or even electronic newspapers in the future. Now researchers from the Universities of Surrey and Sussex have shown that the industrial techniques used to fabricate the sensors in smart phones and tablets could just as easily incorporate AgNWs instead of ITO. [25]

c. Transistors

Thin-film field-effect transistor is a fundamental component behind various modern electronics. The development of stretchable electronics poses fundamental challenges in developing new electronic materials for stretchable thin-film transistors that are mechanically compliant and solution processable. Wearable and biomedical electronic applications demand advanced materials and electronic devices to simultaneously possess deformability, solid state, light weight, visual transparency and low processing cost. Stretchable thin-film field-effect transistor (TFT) would become a fundamental building component enabling a variety of stretchable electronic devices including displays, sensor arrays, thin-film circuits and identification tags for control, data-processing and communication. It has been recently reported intrinsically stretchable solid-state organic light-emitting devices (OLED) and simple pixelated displays. [26,27,28]

5. Bibliography

[1] F. Ma, K.W. Xu

Mater. Res., 21 (2006), p. 2810

[2]

M.T. McDowell, A.M. Leach, K. Gall

Nano. Lett., 8 (2008), p. 3613

[3]

J.R. Greer, J.T.M. De Hosson

Prog. Mater. Sci., 56 (2011), p. 654

[4]

Y. Zhu, Q. Qin, F. Xu, F. Fan, Y. Ding, T. Zhang, B.J. Wiley, Z.L. Wang

Phys. Rev. B, 85 (2012), p. 045443

[5] Kobler, A., Beuth, T., Klöffel, T., Prang, R., Moosmann, M., Scherer, T., … Bitzek, E. (2015). Nanotwinned silver nanowires: Structure and mechanical properties. Acta Materialia, 92, 299–308. https://doi.org/10.1016/j.actamat.2015.02.041

[6] G. Cao, Nanostructures & nanomaterials: Synthesis, properties & applications, Imperial college Press, London (2004)

[7] Luu, Q., Doorn, J., Berry, M., Jiang, C., Lin, C., & May, P. (2011). Preparation and optical properties of silver nanowires and silver-nanowire thin films. Journal of Colloid and Interface Science, 356(1), 151-158. doi:10.1016/j.jcis.2010.12.077

[8] T. Vo-Dinh, A. Dhawan, S.J. Norton, C.G. Khoury, H.N. Wang, V. Misra, M.D. Gerhold

J. Phys. Chem. C, 114 (16) (2010), pp. 7480-7488

[9]

E. Galopin, J. Barbillat, Y. Coffinier, S. Szunerits, G. Patriarche, R. Boukherroub

ACS Appl. Mater. Interface, 1 (7) (2009), pp. 1396-1403

[10]

S.J. Lee, Z.Q. Guan, H.X. Xu, M. Moskovits

J. Phys. Chem. C, 111 (49) (2007), pp. 17985-17988

[11]

S.J. Zhuo, M.W. Shao, L.A. Cheng, R.H. Que, D.D.D. Ma, S.T. Lee

J. Appl. Phys., 108 (3) (2010), p. 034305

[12] Abel, B., Coskun, S., Mohammed, M., Williams, R., Unalan, H. E., & Aslan, K. (2015). Metal-Enhanced Fluorescence from Silver Nanowires with High Aspect Ratio on Glass Slides for Biosensing Applications. The Journal of Physical Chemistry. C, Nanomaterials and Interfaces, 119(1), 675–684. http://doi.org.ncat.idm.oclc.org/10.1021/jp509040f

[13] Schuette, W. M., & Buhro, W. E. (2014). Polyol Synthesis of Silver Nanowires by Heterogeneous Nucleation; Mechanistic Aspects Influencing Nanowire Diameter and Length. Chemistry of Materials, 26(22), 6410–6417. https://doi.org/10.1021/cm502827b

[14] Coskun, S., Aksoy, B., & Unalan, H. E. (2011). Polyol Synthesis of Silver Nanowires: An Extensive Parametric Study. Crystal Growth & Design, 11(11), 4963–4969. https://doi.org/10.1021/cg200874g

[15]

N.C. Bigall, B. Nandan, E.B. Gowd, A. Horechyy, A. EychmüllerHigh-resolution metal nanopatterning by means of switchable block copolymer templates

ACS Appl. Mater. Interfaces, 7 (2015), pp. 12559-12569

[16]

T. Jang, S. Kim, H. Jung, J. Chung, H. Kim, Y. Koh, J. SongLarge-scale nanopatterning of metal surfaces by target-ion induced plasma sputtering (TIPS)

RSC Adv., 6 (2016), pp. 23702-23708

[17]

Erb, Denise. Nanopatterning via self-assembly: Highly ordered metal nanostructures on diblock copolymer templates. IKS institute seminar. No. DESY-2013-00812. DOOR-User, (2013).

[18] Feng, Yuyi. “Silver Nanowire Arrays: Fabrication and Applications.” University Konstanz, 2016, webcache.googleusercontent.com/search?q=cache:HCYsZ7GmVLUJ:https://kops.uni-konstanz.de/bitstream/handle/123456789/38932/Feng_0-406729.pdf%3Fsequence%3D3+&cd=4&hl=en&ct=clnk&gl=us.

[18] Li, P., Liu, N., Yu, H., Wang, F., Liu, L., Lee, G.-B., … Li, W. J. (2016). Silver nanostructures synthesis via optically induced electrochemical deposition. Scientific Reports, 6, 28035.

[19] K. K. Caswell, C. M. Bender, C. J. Murphy, Nano Lett. 2003, 3, 6 6 7– 669.

[20] Finn, D. J., Lotya, M., & Coleman, J. N. (2015). Inkjet Printing of Silver Nanowire Networks. ACS Applied Materials & Interfaces, 7(17), 9254–9261. https://doi.org/10.1021/acsami.5b01875

[21] , ; , ; , ; , ; , Direct Ink-Jet Printing of Silver Nitrate-Silver Nanowire Hybrid Inks To Fabricate Silver Conductive Lines J. Mater. Chem. 2012, 22, 15599–15605

[22] Basarir, F., Irani, F. S., Kosemen, A., Camic, B. T., Oytun, F., Tunaboylu, B., … Choi, H. (2017). Recent progresses on solution-processed silver nanowire based transparent conducting electrodes for organic solar cells. Materials Today Chemistry, 3, 60–72. https://doi.org/10.1016/j.mtchem.2017.02.001

[23] Wang, L., Gao, X., Jin, L., Wu, Q., Chen, Z., & Lin, X. (2013). Amperometric glucose biosensor based on silver nanowires and glucose oxidase. Sensors and Actuators B: Chemical, 176, 9–14. https://doi.org/10.1016/j.snb.2012.08.077

[24] Boland, C. S., Khan, U., Benameur, H., & Coleman, J. N. (2017). Surface coatings of silver nanowires lead to effective, high conductivity, high-strain, ultrathin sensors. Nanoscale, 9(46), 18507–18515. https://doi.org/10.1039/C7NR06685F

[25] Cann, M., Large, M. J., Henley, S. J., Milne, D., Sato, T., Chan, H., … Dalton, A. B. (2016). High performance transparent multi-touch sensors based on silver nanowires. Materials Today Communications, 7, 42–50. https://doi.org/10.1016/j.mtcomm.2016.03.005

[26]

Yu, Z., Niu, X., Liu, Z. & Pei, Q. Intrinsically stretchable polymer light-emitting devices using carbon nanotube-polymer composite electrodes. Adv. Mater. 23, 3989–3994 (2011).

Yu, Z., Niu, X., Liu, Z. & Pei, Q. Intrinsically stretchable polymer light-emitting devices using carbon nanotube-polymer composite electrodes. Adv. Mater. 23, 3989–3994 (2011).

[27] Liang, J. et al. Silver nanowire percolation network soldered with graphene oxide at room temperature and its application for fully stretchable polymer light-emitting diodes. ACS Nano 8, 1590–1600 (2014).

[28] Liang, J., Li, L., Niu, X., Yu, Z. & Pei, Q. Elastomeric polymer light-emitting devices and displays. Nat. Photonics 7, 817–824 (2013).

No comments:

Post a Comment